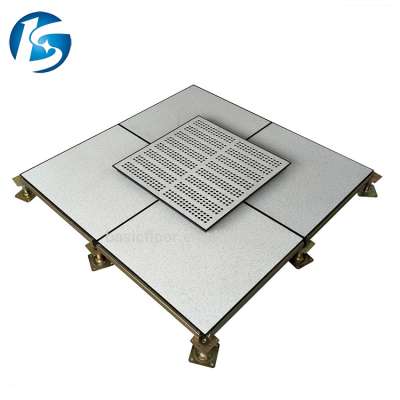

Sell well new type anti-static steel panel perforated raised floor

Description:

Basic Antistatic perforated panels and accessories:Perforated panels are designed to computer rooms for airflow. Basic are able to supply perforated panels of different airflow volumes according to different requirements from customers. Meanwhile , dampers can be applied to perforated panels,so as to control the volume of airflow.

To meet different needs from customers, Basic also supply various kinds of round outlet boxes,square outlet boxes,panels tuyeres,panel lifters and pedestals of different raised height.

Feature:

1.) Size: 600*600*35/45mm

2.) full steel , HPL or PVC or Ceramic laminates

3.) surface punched panel which is hard steel of Shanghai Bao steel,

4.) Manual welding for the bottom square tube, origination in domestic.

5 ) Imported paint, anti-rust.

6.) prevent static validly fireproof, dustproof

7.) exact dimension for the hole of tile and panel ,good ventilation function

8.) 17%~50% ventilation rate, satisfies different environmental requirements

Specification Sheet:

Packaging & Shipping:

Our Services:

Changzhou Basic Company uphold the principle of “a full range,high quality fast”service standards, customer satisfaction as the goal, to the public commitment.

After-sales Service Letter of Commitment:

User quality problems arise in the normal use condition, both steel cementitious bare finish floor and the ceramic raised floor are guaranteed to keep in good repair for 5 years.If quality problems happen in guarantee period, our company will maintain for free.Additionally, our company provides technical support and fittings for life. After-sales service isn’t restricted by time and we will assign technical personnel to solve your problems immediately after receiving telephone or mails and hear feedback idea of users and deal with them in time. If you caught in some problems when using our products, welcome to contact us at any time.

Cmpany Information:

.Changzhou BASIC Computer Room Equipment Co. ,Ltd, established in 1980s, it has 3 factory areas with total land area of 10 hectares, they are Full-steel Anti-static Raised Floor Factory,Anti-static Vinyl PVC factory and Calcium Sulphate Raised Floor Factory. It developed into a current flattop-like business with annual output value and sales amount of ten million dollars, from a home-based workshop with dozens of workers in the initial phase of founding, it specialized in producing and marketing the anti-static floors and raised access floors.

BASIC floors have been sold to Middle East (Qatar, United Arab Emirates, Saudi Arabia, etc), Europe & America (including Belgium, Brazil, Uruguay ,etc) and Southeast Asia (Malaysia, India, Vietnam ,etc).

BASIC Company has successively passed the certifications of ISO9001:2008 international quality management system, ISO14001:2004 environmental management system and ISO18001:2008 occupational health and safety management system. All its products satisfy the national and industrial standards.

“Quality comes first” and “Customers satisfaction is our honor” are BASIC ever-living quality policy. Taking it on oneself to care for the environment, repay the society and love employees and ceaselessly pursuing the objective of “integrity, responsibility, innovation and team”, it would like to work together with numerous friends at the bright future.

Installation :

1.Requirements to laying site:

1)The laying of antistatic raised access floor shall be carried after the indoor civil engineering and decoration and finished.

2)Ground must be flatness,clean,dry and there shall be no any sundry or dust on it .

3)The construction of cable electric appliance,air pipeline and AC system to be arranged under floor surface shall be finished before the installation of floorings.

4)The base of heavy equipment must be firmed,equipment is installed on the base and the base height shall be align with the upper surface of the floor.

5)The construction site must be equipped with 220V/50HZ power supply and water supply.

2. Tools for installation:

Infrared ray level instrument, large push cutter, aluminum alloy ruler, level bar electric hand drill, Mini type marble cutter, pulling nail gun, wire-cutter, steel ruler, nail, pencil, suction disc machine, adz-eye hammer, spanner, screwdriver, floor glue, tool bag ,broom.

3. Construction Procedures:

1)The flatness of floor and the verticality of wall are carefully checked. If any part is found not to be consistent with construction requirements,it shall be reported to relevant department of Part A.

2)The horizontal lines are pulled and fixed and the installation height of floorings is drawn on the wall using ink line.The floor panels shall be on a same horizontal plane. The indoor length and width are measured. The reference position of laying shall be selected properly in order to decrease the cutting the floorings.

3)The pedestals to be installed are adjusted to a same height as required,and then placed on the decussation position of the grid lines.

4)Stringers are fixed on the pedestals using screws, and every are on a same plane and mutually perpendicular.

5)The floor replaced on the assembled stringers using board sucker.

6)If the rest distanceto the wall is less than the length of floor , the floor can be cut into adequate size before installation.

7)During the laying of floorings,blister gradienter shall be used for levelling and the height of floorings can be adjusted through pedestal.

8)In case that heavy equipment is placed in machine room,additional pedestal shall be installed under the equipment base in order to avoid the deformation of floorings.

9)If it is necessaryto cut or open hole on the raised floor,electrical drill shall be used to open in order to avoid the rupture of veneer.

3. Acceptance criteria for the laying of floorings:

1)Either under the floor or the surface of the floor shall be cleaned,to avoid the dust .

2)There is no search and coating peeling on floorings,and regulas are not damaged.

3)The whole of the floor after laying shall be stable and firm. There is no sound and the feeling of shaking when walking on the floor.

4)The regulas must be in a line,and the displacement of adjuacent regulas shall not be more than 1mm.

5)The height difference of adjacent floor panels shall be more than 2 mm.

4.Maintenance Requirements:

1)It is forbidden to directly use sharp tools to carry out construction on the floor surface in order to avoid the damages to the appearance and antistatic performance of flooring surface.

2) During application, no person is allowed to jump onto the floor from high position, and it is forbidden to crudely remove equipment as such operation may damage the floor.

3)When equipment is moved on the antistatic raised access floor,it is forbidden to directly pull the equipment on floor as it may scuff the floor,the equipment shall be lifter before moving.

4)When heavy equipment is to be installed in machine room,it ahall directly place the heavy equipment on floor as deformation may be long-term load bearing.

5)To repair the equipment under the floor, panel lifter shall be first used to remove flooring.It is forbidden to use sharp tools to crudely dismantle and assemble the flooring.

6)During maintenance,dust collector or mop can be used to keep the floor clean. Particularly, measures shall be taken to avoid sprinkling liquid onto floor.

7)Antistatic wax can be polished on the floor surface, in order to protect the floor and ensure the application effect in long time.

5.Opetaing Environment:

The temperature in the room to be laid with antistatic raised floorings shall be 15-35degree,and the relative humility is 45%-75%RH.If the humidity of the computer room is low for a long time,there may be cracks on the floor surface and the strength and the thickness of attaching veneer shall be increased therefore.

FAQ:

Q: Are you trading company or manufacturer ?

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Skype: Cherry3553 , WeChat:XYH3553, WhatsApp: